Anticipating to innovate (Part I)

At SAS we aim to keep up to date, we try to keep abreast of all the developments that improve our manufacturing processes, the products that provide solutions, that improve work, and, in a nutshell, solve existing issues. We are convinced that prefabrication is the future of the construction industry as all factory operations (automation and serialization) can be fully monitored, whilst solutions created on-site are dependent on worker ability. Applying process standardization has enabled us to participate in and lead various projects over the years.

Some of the projects from recent years include:

New factory for new times

In 1999, the decision was taken to build a new factory and in October 2000 the purchase of 210,000m2 in Pira (La Conca de Barberà) Tarragona was completed.

We decided to build a “sustainable” factory that would have minimal impact on the environment. This would entail some upgrades.

A water reclamation and reuse system were designed using a mill to return decanted water that can be reused. This grants a saving of 72% on factory water usage.

Similarly, it was decided that the waste generated by pieces that did not satisfy SAS’s demanding quality control standards would not be sent to landfill, rather it would be ground up to be used again as aggregate for future pieces. This reduces our use of stone and visits to already saturated landfill sites.

Serial production began in the new factory in Pira in February 2004. This factory was designed to also include women in the workplace, which is not commonplace in the sector. Today there are female machine operators operating production machinery, in charge of the concrete batching plant, responsible for the warehouse, as well as working in other areas. This means we have women involved in all manufacturing processes.

Licensed manufacturing and sale

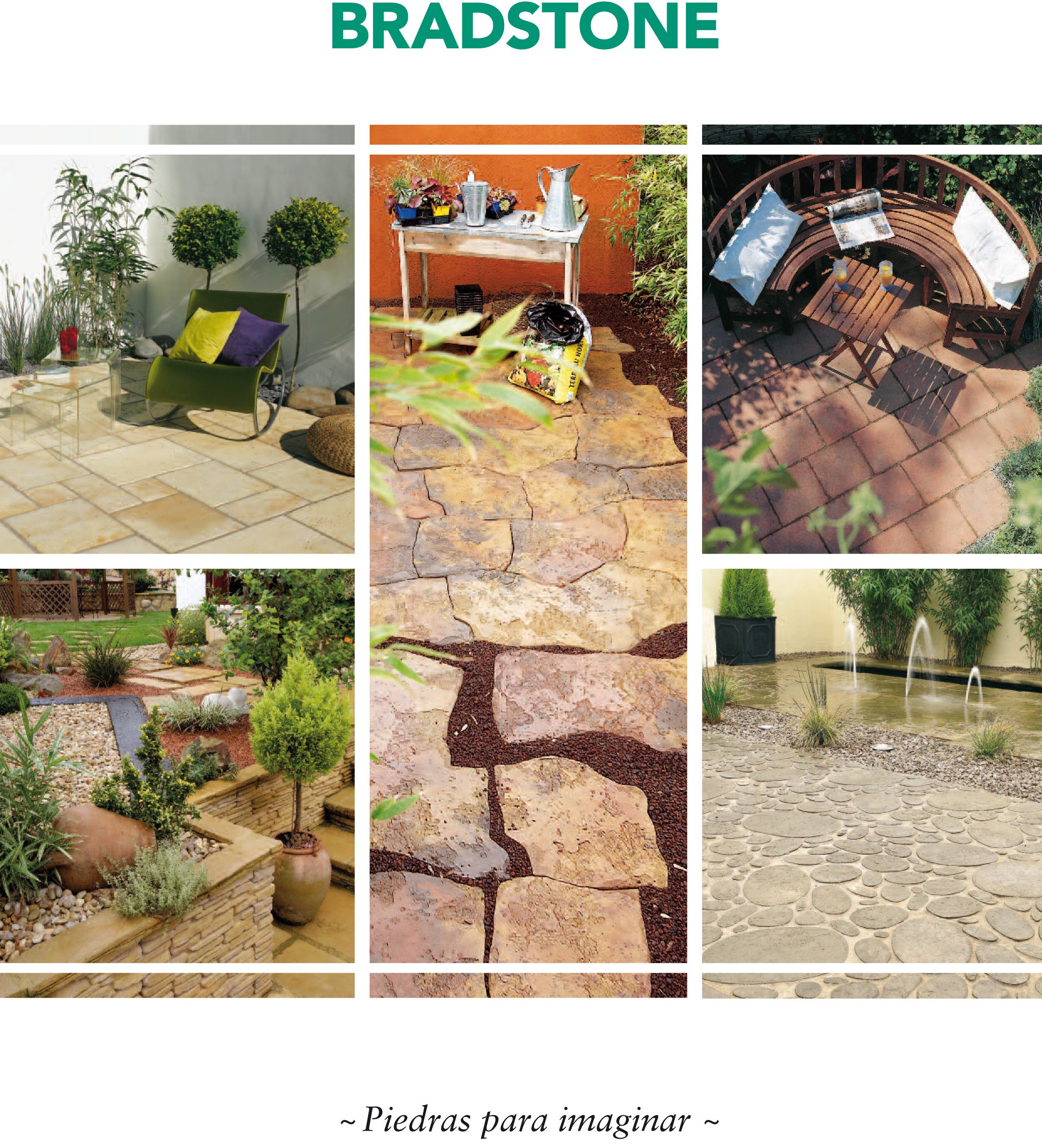

In 2005, licensed production commenced on products from the English company, BRADSTONE. As a production-focused company, it was strange to be manufacturing other companies’ products and paying a royalty to do so too! That decision allowed us to gain a deeper insight into Wet-Cast concrete and cooperate with colleagues from all over the globe as a means of learning how to improve processes and explore new ideas and techniques. This relationship would be the starting point of SAS’ entry into the manufacturing and sale of Wet-Cast products and would consolidate our position as industry leaders in our 120th anniversary.

In view of all our clients’ positive reactions to the BRADSTONE products, in 2006, the decision was taken to sell the products of the Italian firm, MASPE. MASPE had a line of concrete pavements that was truly unique and brought more success for SAS.

In the next SAS Blog post, you can find out more about our improvements and new products that we have developed to keep us at the forefront of the prefabricated concrete industry.