“Dry-Cast” Wall Coping, an icon of quality and service by SAS

In previous blogs, we told you about our range of smooth finish “Wet-Cast” Wall Coping. Today, we want to tell you about its ancestor: the “Dry-Cast” Wall Coping. It is SAS’s best-selling range of products and undoubtedly one of the oldest. In fact, we have been manufacturing “Dry-Cast” Wall Coping since 1977, surpassing any fashion and trends in the industry, demonstrating that it is a timeless and versatile product.

The manufacturing process of “Dry-Cast” Wall Coping is very different from the “Wet-Cast” one. In this case, the elements are produced in metal molds using machines that work through pressure and mechanical vibration. The pieces require about 8 days of maturation. The entire process is highly automated, reducing the margin of error and ensuring that all elements have the same chemical and physical characteristics. When it comes to executing the joints, you can easily create clean connections without any complication.

What are our wall copings made of?

SAS Wall Copings – both the “Dry-Cast” and the “Wet-Cast” range – are made with high-performance concrete, using a mixture of selected natural sand and gravel, high-resistance cement and state-of-the-art additives. The “Dry-Cast” Wall Copings have undergone frost resistance tests according to German and Canadian standards, which are much stricter than ours, and have brilliantly passed them. The color is directly incorporated into the mass, ensuring a uniform coloration in all pieces. Since they do not carry internal reinforcement, SAS Wall Copings do not rust and withstand the test of time very well.

Sloping Wall Coping with visible drip edge. (source: SAS)

A technical and protective product

SAS Wall Copings are the ones that changed the commercial name of this element, transitioning from the more classic term “covering” to “coping” (a piece that covers and protects a wall). In just a few years, the entire industry started using this word to define this piece. This, in itself, explains the importance of this element and the impact it has had on the market. Moreover, along with its unique composition, the absence of metal reinforcement, and the technical detail of the drip edge to protect the vertical walls, makes these pieces perfect for finishing and protecting; you will not find anything better!

Aesthetic appeal and variety of models

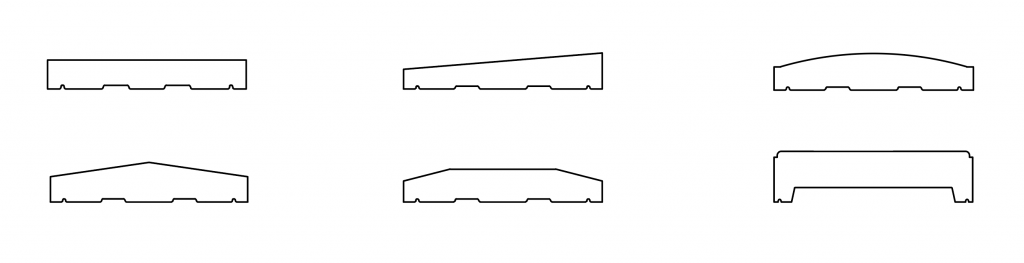

The “Dry-Cast” line is characterized by a smooth but porous finish, similar to natural stone, making it the perfect solution for more traditional constructions. We offer a wide range of models, sizes, and colors, for a total of 277 different options. In our catalogue, you will find 12 width measurements, 2 lengths, and 4 colors: Gray, White, Beige, and Périgord. Moreover, for the past couple of years, we have started manufacturing some models in Anthracite Black color in response to a general interest in the industry and to stay at the forefront of innovation and trends.

Section of some “Dry-Cast” Wall Coping models by SAS. (source: SAS)

SAS offers three Wall Copings exhibitors to be placed at the selling point; we also offer the possibility of creating custom-made exhibitions to see how they might look in your projects. Contact our sales department, and we will guide you throughout the entire process.

Come and discover all the “Dry-Cast” Wall Coping models in our upcoming blog and choose the solution that best suits your needs.

Do you have any doubt? Get in touch with our commercial team and we will provide you with all the necessary information. And remember, hexagonal is always better!