SAS “Wet-Cast” Wall Coping: between minimalism and functionality

What makes SAS Wall Coping unique in its category?

Firstly, our products are continuously evolving through the integration of new technologies and our customer feedback. This enables us to adapt our products to meet the market demands while ensuring they satisfy the specific needs of our customers.

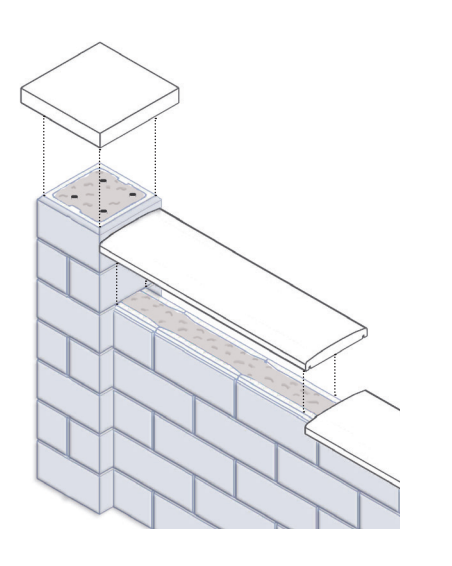

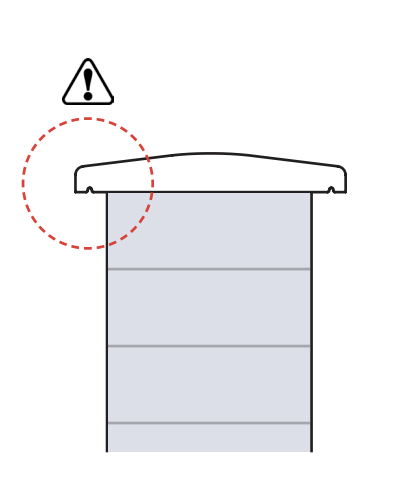

On the left, you can see the laying technique of SAS Wall Coping, and on the right, a view of the characteristic drip edge.

(source: SAS)

All SAS Wall Copings are manufactured without internal reinforcement. This prevents internal oxidation and ensures that the elements withstand the test of time without bursting due to expansions.

Moreover, all models feature a drip edge at the bottom. This ensures that even during heavy rain, water does not come into direct contact with the wall, preventing damage and potential staining caused by moisture.

Finally, the high-performance concrete composition used in the manufacturing of all SAS products guarantees quality, deformation resistance and long-term durability.

On the left, the “Wet-Cast” Double-Beveled Stone, and on the right, the “Dry-Cast” semi-dry finish version. (source: SAS)

What makes the Smooth Finish “Wet-Cast” Slabs the best option?

The difference with the semi-dry finish “Dry-Cast” is the production process and a more minimalist and trending aesthetic. The “Wet-Cast” Wall Coping are manufactured in individual molds that are subsequently demolded to undergo controlled maturation for over 8 days. The consistency of the mixture is more fluid, allowing for a more homogeneous distribution in the mold. Thanks to this mixture, the finish is very smooth, with practically invisible pores and perfectly rounded edges, making it the most contemporary aesthetically pleasing solution for your projects.

The products in this line are the perfect alternative for everyone who prefers polymer wall coping over concrete. Thanks to our manufacturing technique and the characteristics of the mixture, SAS Wall Coping offer many advantages over polymers, making them ideal for high-quality construction projects:

- Manufactured with high-alumina self-compacting concrete (HAC) with a high content of fine materials and state-of-the-art superplasticizing additives, providing superior strength and stability compared to other products.

- Rounded edges and super smooth finish resulting in water absorption below 2,5%. Different sections (slab, double-beveled, sloping, and chamfered) available in two lengths: 50 and 100 cm. Drip edge for proper water evacuation.

- Advantages over polymers: no warping, no breaking, no color fading, high abrasion resistance, greater on-site stability, unaffected by temperature changes, surface does not crack due to sun exposure or over time, etc.

Do not put practicality before aesthetics when you can have it all with SAS “Wet-Cast” Wall Coping. Choose SAS!

Do you still have doubts about our smooth finish “Wet-Cast” Wall Coping? If you want to know more about their characteristics, do not hesitate to contact us. Our sales team is at your disposal to help you choose the best solutions for your projects.